About 46 miles down Jhelum river from Srinagar, just past Baramulla town, the topography changes drastically, hence the nature of river also changes. The mountains become edgier and the river becomes rougher. The valley of Kashmir falls rapidly, it slopes down. At places, water desperately seeks place to escape. At places, it physically cuts through them using routes violently carved out by it over ages. The beauty of all this seems a cold naked fact to the eye. The Jhelum river within 100 miles has an average fall of 50 feet per miles, with a minimum flow of around 3,000 cubic feet per minute. Ancient eyes of Kashmiris must have witnessed these cold facts and given rise to the story of Varah and the draining of Satisar, giving rise to the mythical origins of the valley.

Just past the ancient pilgrimage spot of Buniyar, it is here at Rampore in Uri area of Baramulla (the ancient Varaha Moh), a human endeavour about hundred years ago shaped the present semblance of Kashmir. A river was tamed to produce the life force of modern human life: electricity.

After the devastating flood of 1903, in 1904, skills of Canada born Major Alain de Lotbinière of Royal Engineers, after having successfully harnessed Cauvery Falls in Madras for electricity to be used for Kolar gold-fields in Mysore, were sought by Maharaja of Kashmir Pratab Singh for taming Jhelum river.

The idea was to produce electricity using the wild power of the river, and then use that electricity to dredge the river, to control it further.

Lotbinière came up with an extensive plan that made brilliant use of local topology and resources to produce one of the great marvels of engineering for its time.

[Lotbinière] therefore came to the work in Kashmir in September 1904 fully primed with the knowledge of all the latest developments of electrical science, and at once conceived the idea of harnessing, not any of the minor rivers of Kashmir, but the river Jhelum itself, and selected a spot a few miles above Rampur where he might entrap some of the water, lead it along the mountain-side at practically a uniform level, till he could drop it through pipes on to turbines—very much in the same manner as a mill-stream is led along and then dropped on to a water-wheel—and so by setting in motion various machines generate electrical energy.

The theory of the electric installation is then very simple. The valley falls rapidly. At the part selected it falls about 400 feet in 6½ miles. Some of the water is taken out and kept at about the same level so that at the end of the 6½ miles it has a fall of 401 feet. Consequently when it is dropped those 400 feet it falls with immense force and velocity. By most ingenious machinery this force is turned into electrical energy, and then transmitted by wires to wherever wanted—it is hoped even to the plains of the Punjab, to Rawal Pindi at least.

[…]

Water for the present project has been taken out a couple of miles above Rampur at a most charming spot, where the river comes foaming down over innumerable boulders, and the banks are overshadowed by the same graceful deodar trees which clothe the mountain-sides. Here very strong and solid masonry headworks and regulating sluices have been built under the lee of some friendly boulders; and elaborate precautions have been taken to protect these headworks from the impact of the thousands of logs which are annually floated down the river by the Forest Department to be caught and sold in the plains below.

From these headworks what is called a flume has been constructed in which the water will run along the mountain-side to the forebay or tank immediately above the generating station. This flume, answering to the channel which conducts the water to a flour-mill, is to the eye absolutely level, but it has in reality the very small drop of 1·05 feet in 1000 feet—just sufficient to make the water run easily along it. Its length is about 6½ miles; and the main difficulty in the whole project was found in constructing it. A road or even a railway when it comes to an obstacle can very likely, by a change in the gradient, rise over it or under it. But this flume had to go straight at any obstacle in its way, for it obviously could not rise, and if it were lowered it could not rise again, and so much horse-power would have been lost at the far end. The flume, in fact, once it was started off had to take things as it found them and make the best of them. The first obstacle was a great spur of boulder conglomerate. This had to be cut down into to a depth of forty feet. An arched masonry passage had then to be made, and the whole covered over again. Five torrents were negotiated by passing them clean over the flume. Over six other torrents the flume—here made of wood—had to be carried on strong iron bridges. And six tunnels were made through projecting rocky spurs. Only one-third of the 6½ miles’ length of flume could be built of masonry, and the remainder had necessarily to be built of timber. This portion had an internal section of 8-1/3 feet by 8½ feet, and was constructed of tongued and grooved, machine-planed, deodar planking 2¾ inches thick, supported on cross frames 3½ feet apart.

[…]

On emerging from the flume the water enters the brick-lined tank or reservoir called the forebay, where it settles for a moment before descending the great iron pipe which conducts it on to the machinery in the power-house below. In this forebay there are, of course, sluice gates to regulate the flow, and shut it off altogether at one or all the pipes. And there is also a spill channel for the water to flow away to waste when it is not wanted.

Then four hundred feet below we come to the power-house, with all the most modern electrical plant transported from America, and much of it from the farthest western coast of America, across the Atlantic and the Indian Oceans, right across India, and then for 150 miles by road over a range 6000 feet high. The water-power made available by the flume is capable of generating 20,000 horse-power; but as that amount of power is not at present required, electrical machinery to develop not more than 5000 h.-p. has as yet been put in, though space and all arrangements have been provided in the power-house for machinery to develop 15,000 h.-p. more whenever that is required. The machinery is by the General Electric Co. of New York, and the generators supplied are of the three-phase 25-cycle type. The water-wheels upon which the water from the forebay, led down the pipes and contracted through a nozzle, impinges with such tremendous velocity that a hatchet could not cut the spout, are made of specially toughened steel, and are so cunningly designed that the utmost effect is obtained from the fall of the water, and that immediately the water has done its work it is allowed to pass away at once through a waste channel back again into the river without further impeding the machinery. These wheels were supplied by Abner Doble of San Francisco. They are sent revolving with immense rapidity—five hundred revolutions per minute, or eight every second—and they cause to revolve the electrical generators which are placed on the same axis, and thereby electric energy is generated. By a series of very ingenious machines this electric energy is regulated and conducted to the transmission wires which are at present carried through Baramula to Srinagar, and which will transmit the power at the extremely high voltage of 60,000 volts from the generating station to the spot where the power is required.

|

| Flumes running along the hills The plant was commissioned in 1905 and fully operation by 1907 |

|

|

The water from Jhelum was diverted about 8 miles higher up into a canal, running partly on the surface but mostly in a wooden tube or flume, 8 feet square, which ran along hillside. |

The fall at the power house was about 430 feet. The result of the effort was about 5000 horse-power which was used for dredging the bed of the Jhelum River and neighbouring marshes, and thus preventing floods (something that was later stopped in around 1917 [Kashmir Ecology and Environment: New Concerns and Strategies by Saligram Bhatt]), and for reclaiming some 60,000 acres of cultivable land. Between 1908 and 1912 about 6100 acres of land was reclaimed from Wular Lake. The electric power was also be used for heating the water basins in the silk factory and turning the reeling machinery, as well as for lighting Srinagar making it the second city in the sub-continent to be electrified. There were also plans for providing electricity to industrial operations in Rawalpindi, Murree and Abbottabad. Also, to the proposed Srinagar-Abbottabad railway line.

The river cutting into the plant.

The machinery came from Hungarian firm Ganz

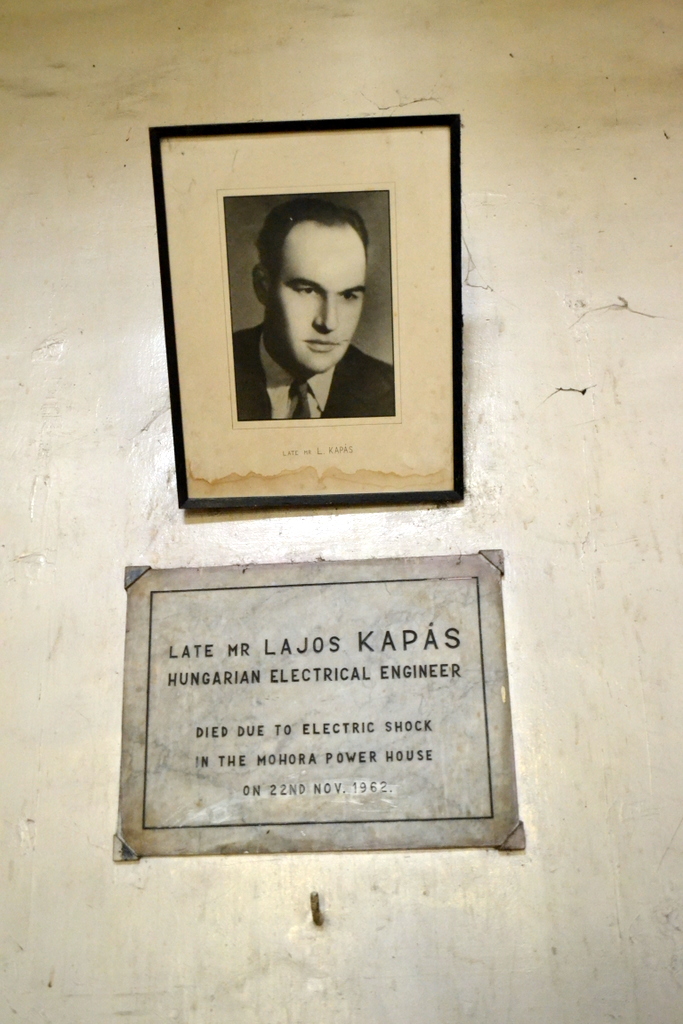

Memory of Hungarian Electrical Engineer Lajos Kaps who died on 22nd November 1962 due to electric shock. The lore has it that he had a nail in his shoe and the incident happened during the inauguration.

Control room for transmission

Remnants of the power plant.

The river from the New Mohra Power Plant. The river is great for fishing at some of the nearby spots.

None of the old machinery can be seen. However, some later additions can be seen laying around. Here, a piece from British Company Winget.

The men who used to work in the old powerhouse. They hope that the place will be converted into some sort of heritage. For ages, the powerhouse was the only source of employment for locals.

These men remembered that the land for power plant was purchased by the Maharaja from local inhabitants.

Biscuit tin roofed temple next to the old post office of Mohra. Biscuit tin roof for temple was in vogue in Kashmir in early 20th century.

|

The two local men who showed me the spot across the road from where water was dropped onto the turbine. They also mentioned a reservoir up the hills. We didn’t have time for that. |

“In 1899 my grandfather left the Potteries in England as an inventor/electrical engineer and joined Balmer Lawrie in Calcutta. They had just started an Electrical Division and secured contracts ‘up country’. Family records show that William Hodgkinson worked in Kashmir on a hydroelectric power station and his first son (my uncle) was born in Gulmarg in March 1909. “